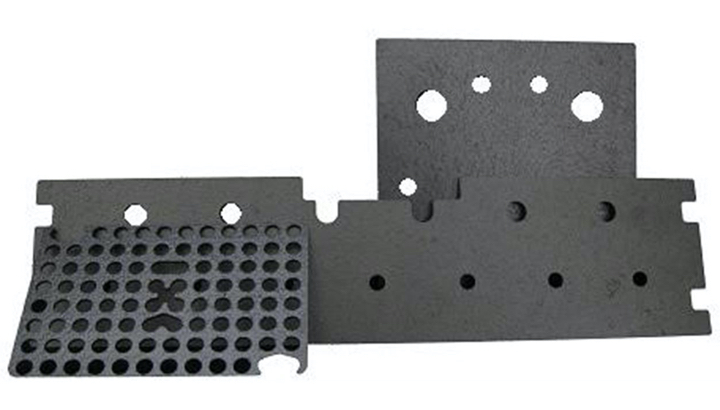

Ceramics Products

Pyrolytic Graphite Coatings

Ultra-pure, high-performance

Popular as a coating for sealing machined graphite hardware, pyrolytic graphite (PG) forms an impermeable protective layer and possesses mechanical, thermal and electrical properties beyond what is achievable with conventional graphite. An ultra-pure product, PG is near theoretical density and is highly anisotropic (300 W/m-K in ab direction, 3.5 W/m-K in c). PG is chemically inert and is stable at extreme temperatures (up to 3000°C).

Features and Benefits

- Chemically inert to act as a protection layer against certain chemical corrosion

- Ultra-high purity minimizes risk of contamination

- Stable to 3000°C to allow for dependability in high-temperature applications

- Impermeability allows for use in high-vacuum applications

- Self-lubricating to eliminate the need for special tooling during machining

- Low etch rate results in an etch-resistant layer in certain chemical environments

- Directional electrical and thermal characteristics can be utilized as electrical heating elements and heat shield materials at high temperatures

- Non-dusting allows for use in a vacuum environment

Recognized as the global technology leader in engineered coating solutions, Momentive Technologies has extensive graphite machining and measurement capability to handle your customized requirements. This specialized graphite is available in plates, machined shapes or as a coating on graphite. Our team of expert engineers is always here to help you design the right solutions for you and your specific applications.

Potential Applications

- Semiconductor applications, including sputtering targets, ion beam grids, ion implant hardware, liquid phase epitaxy hardware and crystal growth

- Thermal insulators

- Metallurgical applications

- Thin film manufacturing

- Pharmaceutical manufacturing

- Graphite manufacturing

- Military equipment

- Heater elements

Download the product datasheet

Pyrolytic Graphite and Coatings-2024

* indicates required fields

Get More Information

Pyrolytic Graphite and Coatings-2024

* indicates required fields