Ceramics Products

Heaters, E-chucks and Modules

Improved thermal uniformity at higher temperatures

Features and Benefits

- Thermal shock resistant and thermally stable materials allow continuous operation up to 1500°C without compromising the life of the heater

- Fast cycle times and ramp rates more than 100°C/sec create high throughput and power saving

- Tunability in multiple zones, overall design versatility and 3D features result in superior wafer thermal uniformity

- Superior electrical resistivity and the ability to tune resistivity allow integration of high-temperature electrostatic chucking

Potential Applications

- Semiconductor processing equipment such as ion implantation, sputtering, evaporation, MBE, ALD, MOCVD, PECVD and RTP

- Metal evaporation and molten metal processing equipment such as OLED electrodes and CIGS solar cell processing equipment

- High-temperature glass forming

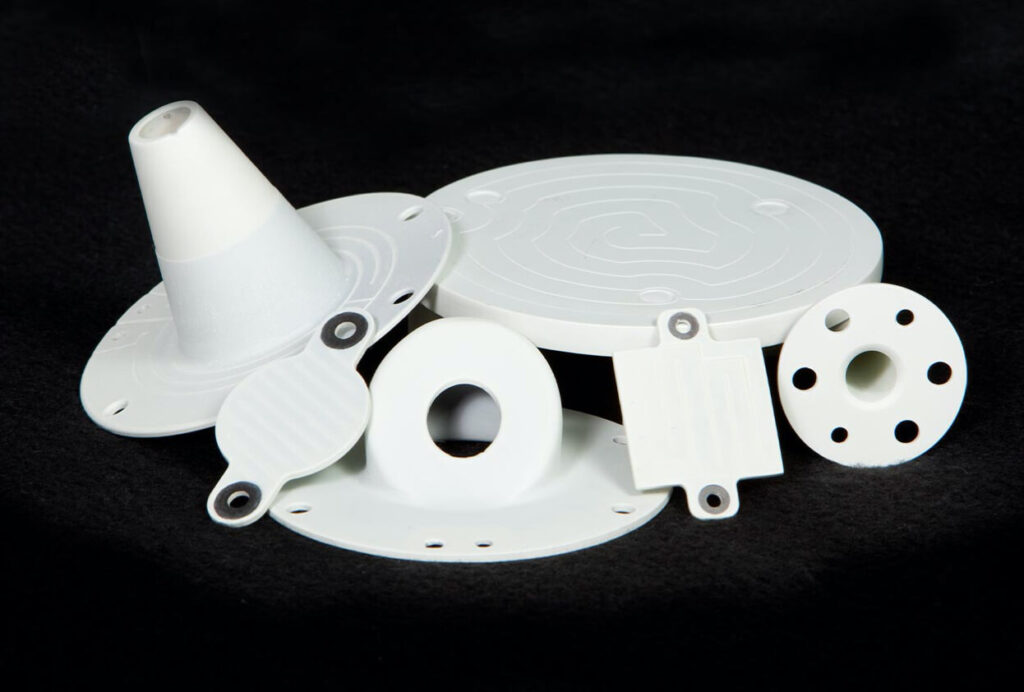

Momentive Technologies manufactures pBN/PG heaters, TaC heaters, heater modules and thermal levelers to your exact thermal, power and size specifications. We have a full-service analytical lab and team of expert engineers to help you design the right solutions for you and your specific applications.

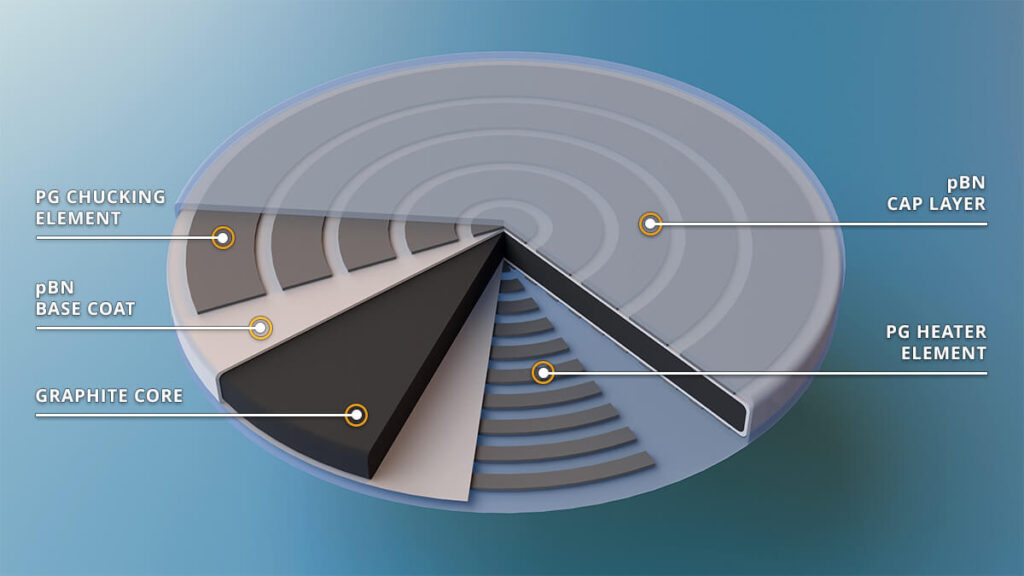

pBN/PG heaters operate at 1700°C and higher with excellent thermal uniformity (2°C on wafer) in an ultra-high vacuum. As nonbrittle refractory materials, they owe their exceptional purity to a high-temperature chemical vapor deposition production method which makes them chemically inert to most corrosive gases and liquids and unaffected by most molten metals. Momentive Technologies can even custom-design heater chucks (ESC) for your high-temperature (up to 1000°C) wafer handling needs.

Extreme thermal stability and chemical resistance

TaC coated graphite heaters provide a more robust heating solution that enhances the life of heaters in harsh environments, reduces equipment maintenance cycles/costs and increases production yield. TaC heaters are stable above 2200°C and offer resistance to H2, NH3, SiH4 and CH4.

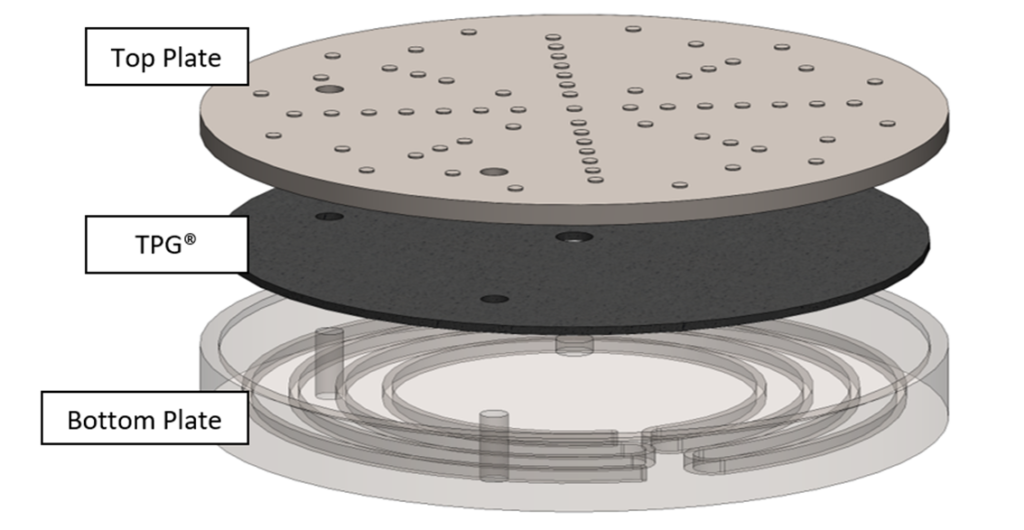

Unique TPG (thermal pyrolytic graphite, 1500W/mK)-based levelers significantly improve the uniformity of new module/pedestal solutions or provide a drop-in uniformity upgrade to existing pedestals. Decades of supplying thermal management heat sinks to the aerospace and military markets combined with our unique understanding of the semiconductor heater market allow our unique thermal levelers to deliver three times better uniformity. And it all can work in coordination with existing heating solutions to improve yields and increase throughput.

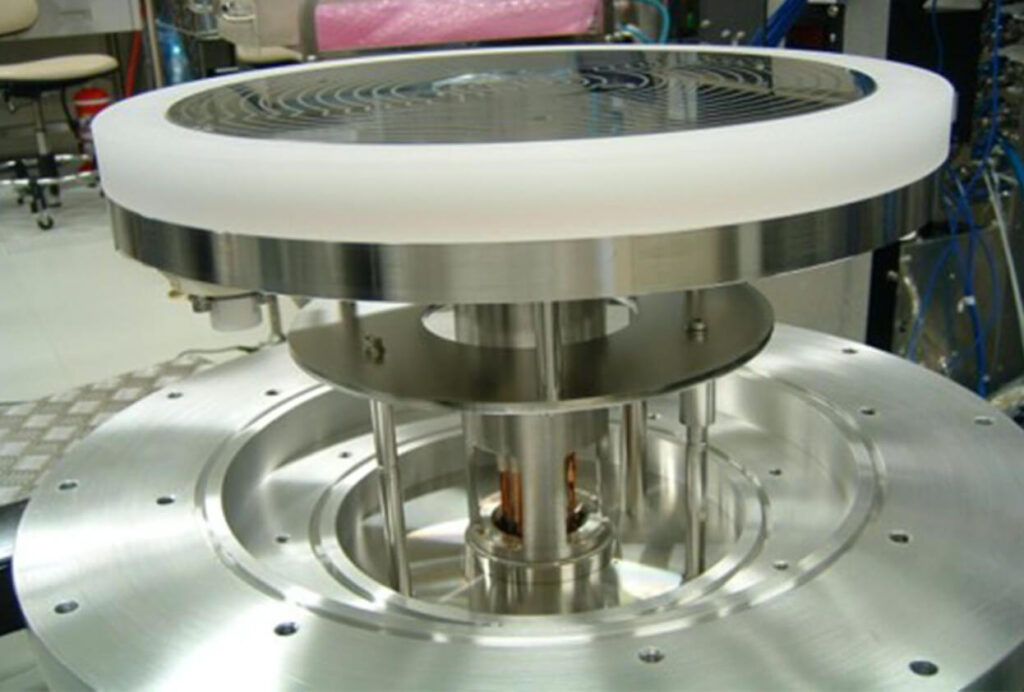

Modules

Customized plug-and-play integrated modules containing pBN heaters and/or chucks offer superior thermal uniformity, higher throughput, longer life and easier maintenance.

Get More Information

Heaters, E-chucks and Modules-2024

* indicates required fields