Ceramics Products

High Thermal Conductivity Heat Sinks

Increased power output and product reliability

Encapsulating our high thermal conductivity (typically 1700W/mK) Thermal Pyrolytic Graphite (TPG) material within a structural metal or ceramic shell, Momentive Technologies has developed a complete line of high–thermal conductivity heat sinks. Our products are an excellent choice for board- and die-level systems where maximum thermal dissipation is required to provide maximum power and performance. Encapsulating TPG within a metal or ceramic provides the structural integrity and durability (shock and vibration, hermiticity, etc.) to survive in aerospace and military applications. Our products have been used for decades and are available as follows: 1) Board-Level – TC1050; 2) Die-Level – TMP-EX; 3) Strap – TMP-FX and 4) Raw Material – TPG.

Features and Benefits

- Thermal conductivity 8X that of aluminum and 4X that of copper allows operation at up to 60% more power or 30% reduction in thermal resistance

- Low thermal interface resistance produces better heat transfer across interfaces

- Lighter than aluminum to enable applications in aerospace and mobile industries

- Adjustable coefficient of thermal expansion enables direct bonding of semiconductor dies and ceramics components to heat sinks

- Hermeticity higher than 10E-8 atm. cc/s removes risks of outgassing and galvanic reaction corrosions

- Vibration and shock resistance help survive harsh environments such as military applications

- Machinable to fit specific form factors for different applications

- Plateable to prevent surface corrosion

Our team is ready to apply our TPG-based technology to solve your thermal management or power issues. Not only can our parts be made to your exact specifications (size, metal, CTE, plating and performance), but we also have the capability to perform supporting testing such as thermal conductivity, thermal modeling, bonding strength, thermal expansion, hermiticity and dimension control to ensure improved performance of your system. We are also AS9100 certified. Our team of expert engineers is always here to help you design the right solutions for you and your specific applications.

Potential Applications

- Heat spreaders in electronic packaging applications

- Thermal cores in PWBs

- Heat sinks

- LED thermal management solutions

- Pharmaceutical primary packaging

- Avionics thermal cores

- Satellite traveling wave tube (TWT) mounts

- Cold plates in radar systems

- Thermal straps

- Unmanned aerial vehicles

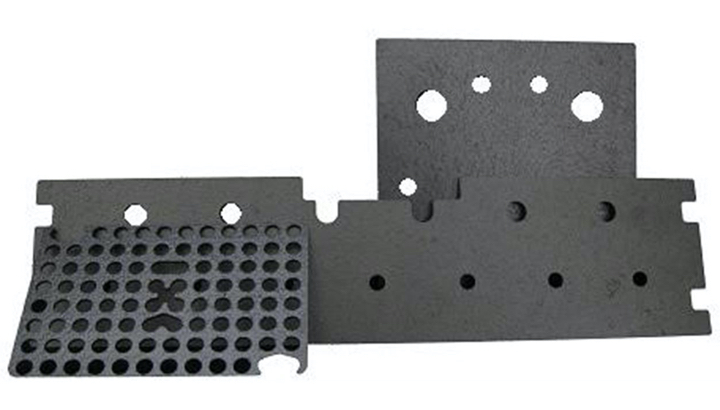

TC1050

Whether you need more power loading for your printed circuit board, more heat dissipation or weight reduction, our TC1050 can answer the challenge. Based on our enabling Thermal Pyrolytic Graphite (TPG) material, we have developed our board-level product line of heat spreaders, heat sinks and cold plates. With over 25 years of serving telecommunication, satellite, military aircraft, radar systems and unmanned aerial vehicles markets, we have solved some of the most difficult thermal issues and won supplier quality awards while doing so. Capable of reaching over 1050 W/m-K, our parts are typically encapsulated with stainless steel or aluminum to match the structural integrity of their monolithic counterparts.

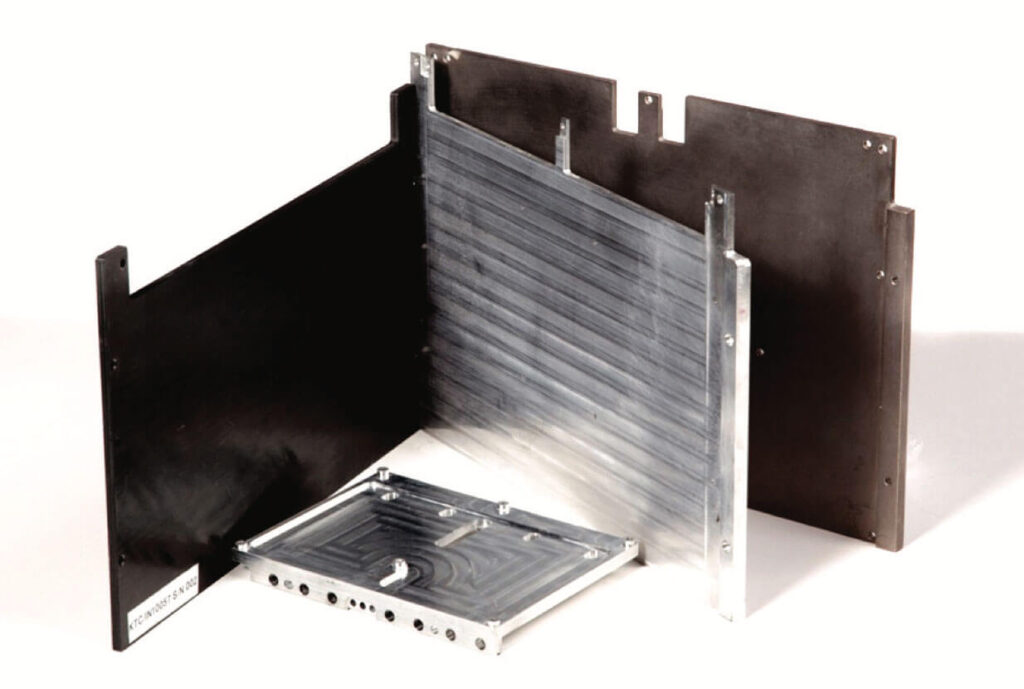

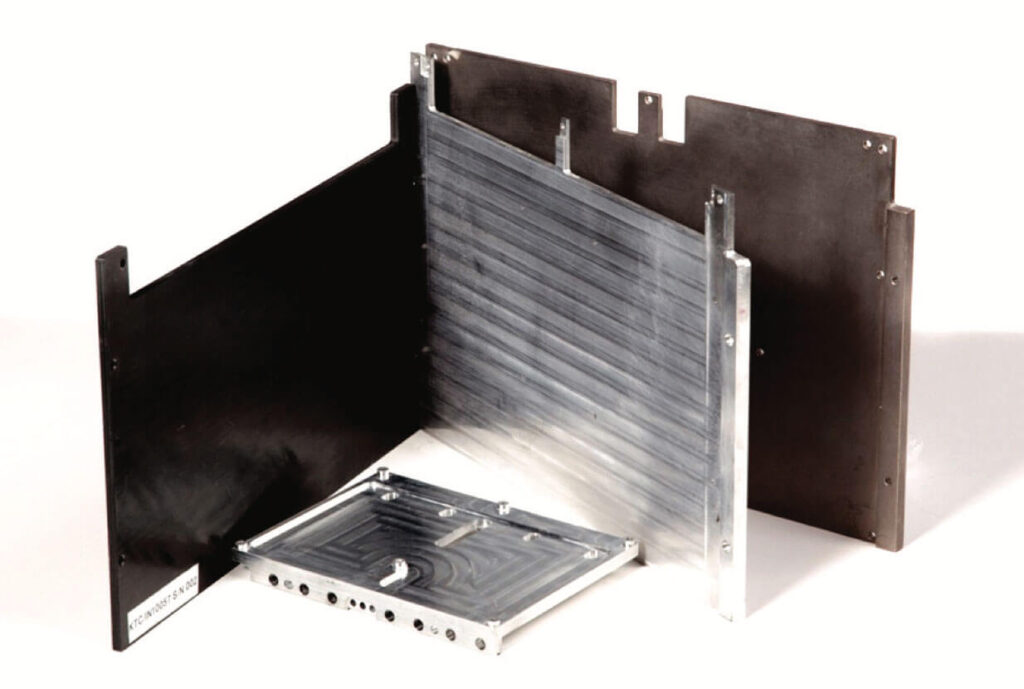

TMP-EX

Our chip-level solution can be a heat sink, carrier or flange with a TPG core encapsulated in Cu, WCu, MoCu or AlSiC to match the structural integrity of the monolithic counterparts and CTE to the semiconductors.

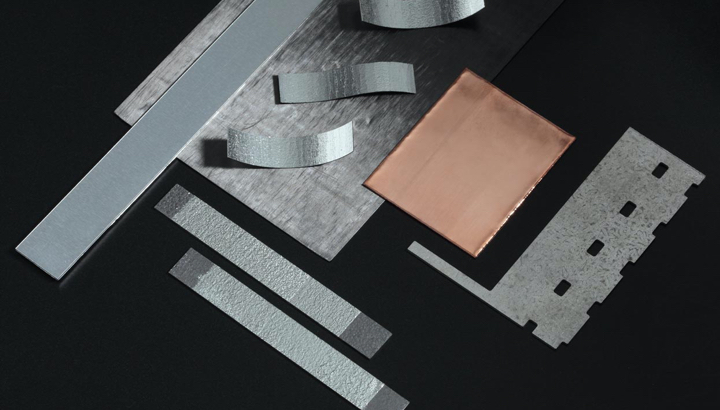

TMP-FX

Laminated or coated with Al, Cu, Sn or Au metal, TMP-FX provides high heat spreading power and flexibility for thermal management in tight spaces. TMP-FX is used primarily as a thermal strap or heat spreader.

TPG

Thermal Pyrolytic Graphite (TPG), a unique synthetic material produced via chemical vapor deposition by Momentive Technologies, contains layers of highly oriented stacked graphene planes and exhibits excellent in-plane thermal conductivity (>1500 W/m-K) and very low density (2.25g/cm3) compared to regular metals.