Home | Materials | Fused Quartz Materials | Quartz Properties | Usage Guidelines

Quartz Properties:

Usage Guidelines

Fused quartz stands firm at room temperature, yet when exposed to high heat, it reveals its adaptability—softening gracefully without a sharp melting point like crystalline materials. Its transition from solid to plastic-like behavior is a journey through the transformation range, where viscosity changes fluidly with temperature. This remarkable flexibility reflects the power of resilience, showing us that even the strongest can bend and adapt when faced with intense pressure, while still maintaining their core integrity.

Cleaning of Fused Quartz

- The products should be washed in deionized or distilled water with a degreasing agent added to the water.

- Fused quartz should then be placed in a 7% (maximum) solution of ammonium bi-fluoride for no more than 10 minutes, or a 10 vol % (maximum) solution of hydrofluoric acid for no more than five minutes.

- Etching of the surface will remove a small amount of fused quartz material as well as any surface contaminants.

- To avoid water spotting, which may attract dirt and cause devitrification upon subsequent heating, fused quartz should be rinsed several times in deionized or distilled water and dried rapidly.

- Use of clean, cotton gloves at all times is essential to reduce possibility of contamination.

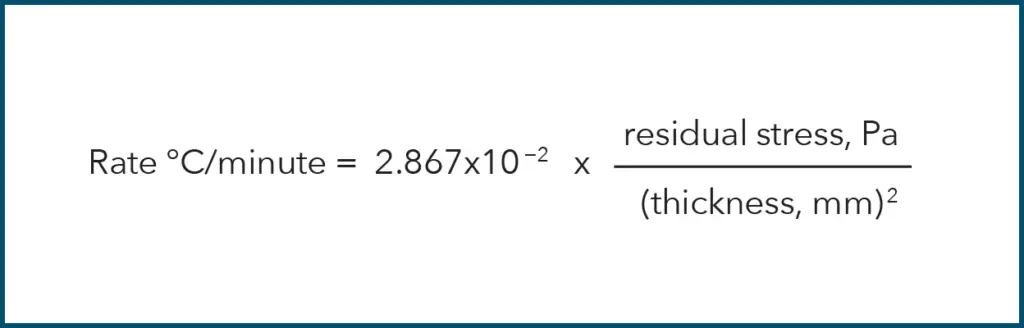

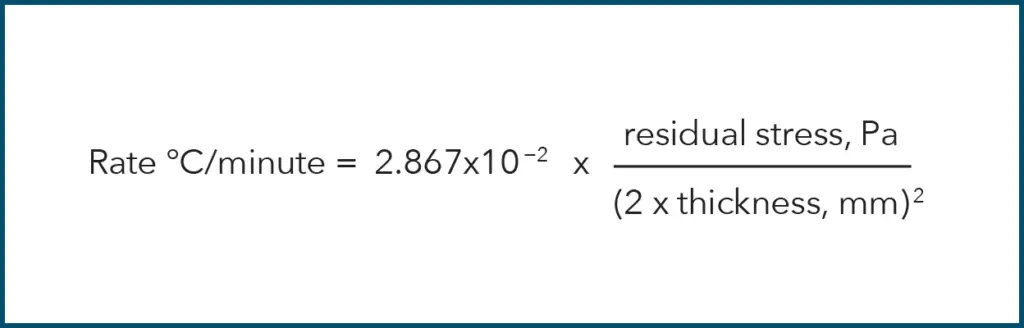

Annealing of Fused Quartz

Fused quartz, like other vitreous (glassy) materials, may have stress after thermal treatment. To avoid this stress, the glass must be cooled properly. The principles of annealing are:

- Elevate the temperature of the glass to a point where the stress is relieved.

- Hold at this temperature until the entire body of the glass reaches temperature equilibrium.

- Cool the glass slowly to a temperature where the glass is rigid.

Handling of Fused Quartz

Like any material that is expected to provide a design life at high temperatures, fused quartz demands some care in handling and use to achieve maximum performance from the product.

Storage

Elevate the temperature of the glass to point where the stress is relieved.

- Hold at this temperature until the entire body of the glass reaches temperature equilibrium.

- Cool the glass slowly to a temperature where the glass is rigid.

Surface Cleanliness

- Contamination in almost any form is detrimental.

Alkaline solutions, salts or vapors are particularly deleterious. - Handling with bare hands deposits sufficient alkali from perspiration to leave clearly defined fingerprints upon devitrification.

- Drops of water allowed to stand on the surface will collect enough contamination from the air to promote devitrified spots and watermarks.

- Surface contamination promotes nucleation of the cristobalite.

Rotation Procedures For Fused Quartz Furnace Tubes

The following procedure has been used to create an even layer of crystobalite on diffusion tubes in order to increase resistance to devitrification.

- Place tube in furnace at 1200°C, and rotate it 90° every two hours for the first 30 hours.

- If the working schedule does not permit adherence to this procedure, place the tube in a furnace at 1200°C and rotate it 90° every two hours for the first 8 hours, then reset the furnace to operating temperature.

- This procedure helps minimize sag at high temperature to increase the lifetime of the diffusion tube, assuming sufficient mechanical support is designed into the furnace.

Solarization

- Fused quartz made from natural raw material solarizes or discolors upon prolonged irradiation by high energy radiation (such as short UV, X-rays, gamma rays and neutrons).

- Resistance to this type of solarization increases with the purity of fused quartz.

- Synthetic fused silica is highly resistant to solarization. Solarization in fused quartz can be thermally bleached by heating it to high temperatures.

Dissociation

- Heating fused quartz to elevated temperatures (ca. 2000°C) causes the SiO2 to undergo dissociation or sublimation.

- This is generally considered to be: SiO2 → SiO + ½O2.

- When flame-working fused quartz, there is a band of haze or smoke which forms just outside the intensely heated region. The haze presumably forms because the SiO recombines with oxygen from the air (and perhaps water) and condenses as extremely small particles of amorphous SiO2.

- Haze can be removed from the surface by heating gently in the oxy-hydrogen flame.

- Usage GuidelinesThe dissociation is greatly enhanced when the heating of fused quartz is carried out in reducing conditions.