Ceramics Products

pBN Heaters & Electrostatic Chucks

For High Temprature Semiconductor Processing

pBN Heaters and Chucks (ESC)

pBN/PG heaters operate at 1700°C and higher with excellent thermal uniformity (2°C on wafer) in an ultra-high vacuum. As nonbrittle refractory materials, they owe their exceptional purity to a high-temperature chemical vapor deposition production method which makes them chemically inert to most corrosive gases and liquids and unaffected by most molten metals. Momentive Technologies can even custom-design heater chucks (ESC) for your high-temperature (up to 1000°C) wafer handling needs.

Wafer handling at elevated temperatures can be challenging. Pyrolytic Boron Nitride Electrostatic Chucks (pBN ESCs) can hold wafers at temperatures exceeding 1000°C, making them the most versatile ESCs on the market. Wafers can be kept within very tight temperature ranges due to the high-density, multizone heating elements. pBN ESC’s high thermal shock resistance means it is mechanically robust even when exposed to rapid temperature swings.

- Momentive Technologies Pyrolytic Boron Nitride Electrostatic Chucks offer ultra-fast J-R chucking at the widest range of temperatures on the market, from 0 to 1000°C

- The materials selected for our heaters result in thermal shock resistance and exceptionally low thermal mass allowing for ramp rates of 100°C/min

- pBN is a fully dense material, making it ultra-high vacuum ready

Key Features

- Power Density over 50 watts/cm2

- Chucking force of up to 100g/cm2

- Up to Ø320mm (12.6”) in diameter

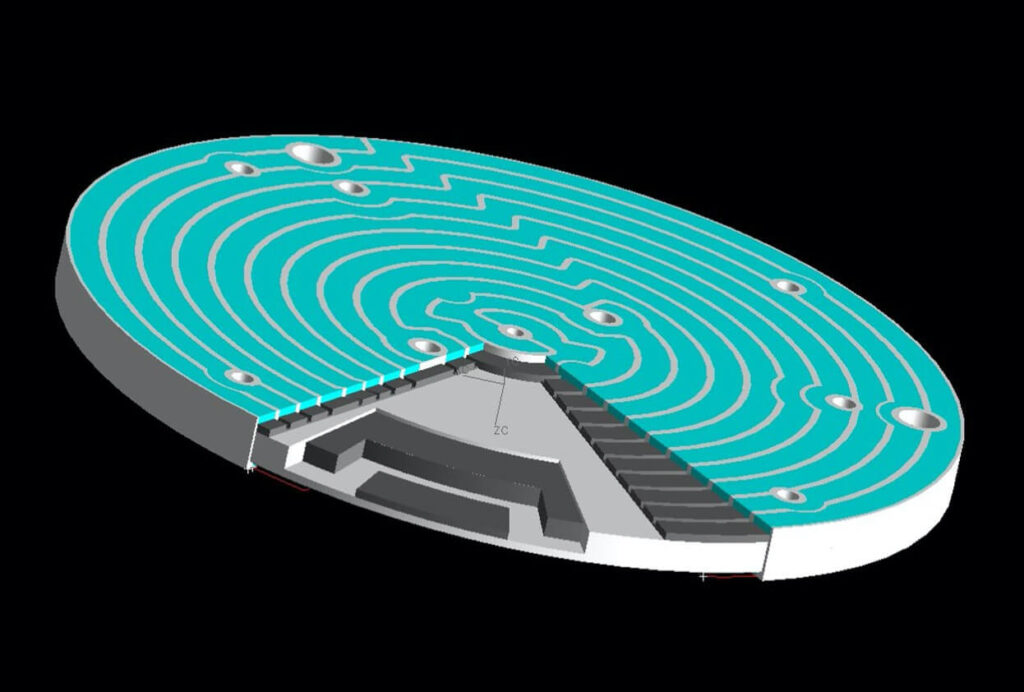

- High density heating elements provide up to 95% coverage of surface area

- Highly customizable mutli-zone heating and ESC capability for maximum temperature control

Standard Features Capability

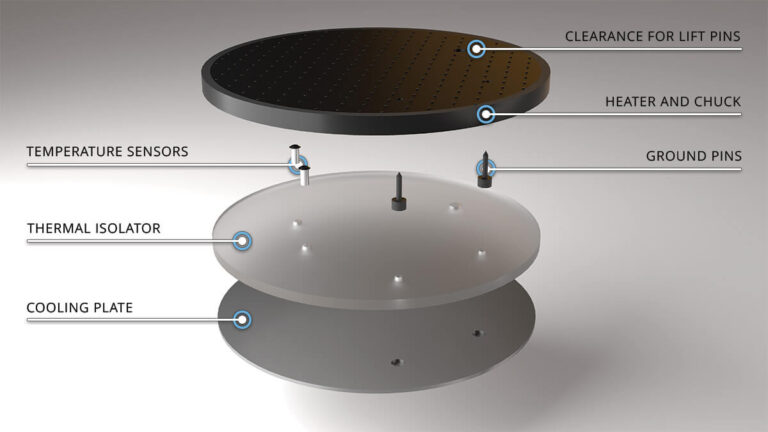

Momentive Technologies pBN ESC Modules can be equipped to handle even the most complex control scheme. Multi-zone heating, multi-zone chucking, backside gas, focusing rings and mesas are just a few of the features we can integrate into your custom design.

Momentive Technologies pBN heaters and ESCs have best in class temperature uniformity. The ESCs are manufactured via unique multistep CVD process. This process allows for high heating element densities and complex element layouts customized to your unique environment.

Manufacturing and Support

- High density heating elements result in excellent thermal uniformity

- Modules are customized to match each customer’s specific requirements

- Our team of application development engineers utilize a combination of thermal and fluid modeling to ensure our modules have the highest performance by working with our customers to exactly match their environment

In House Capabilities

- Testing capabilities

- Simulation

- Design

Get More Information

pBN heaters and electrostatic chucks